Services of PowerKont

Application remarks for clamps and connectors

Application remarks for clamps and connectors

When talking about choosing clamps and connectors for heavy current application,

a few basics should always been taken into consideration.

Main issue is the contact technology and the mechanical stability.

The latter is normally no problem, as the needed material thicknesses for covering the electrical requirements, are automatically leading to a clamp design with more than sufficient mechanical stability.

Much more interesting is, in what way a good qualitiy long term resistant heavy current contact will be guaranteed through the clamp design.

Especially as exactly in this point you can find the biggest differences between products of various manufacturer.

During the 60ties to the 80ties of last century, the german speaking parts of Europe have developed their own 'philosophy', with focus on design, material composition, production of covers, number of covers, and material and size of the used screws, which was verfied through many tests and reports. All these parameters were influencing the internal specifications of the german speaking utilities strongly, and are still today base for their acceptable technical choice.

Most clamps and connectors from foreign manufacturers are not designed in that way, as in other countries very often total different ways of design were followed.

This has a big influence on the assembly process and applicable usage of foreign clamps.

Screws have mostly total different strength classes, number of covers and production method of covers (casted instead of forged --> with much less elasticity) are the result, and have to be considered when choosing a clamp for a specific purpose, as this is influcencing the quality of good long term heavy current contacts significantly.

A wrong choice of clamps could lead to extremely high failure costs, compared to the relative small purchasing price of the products.

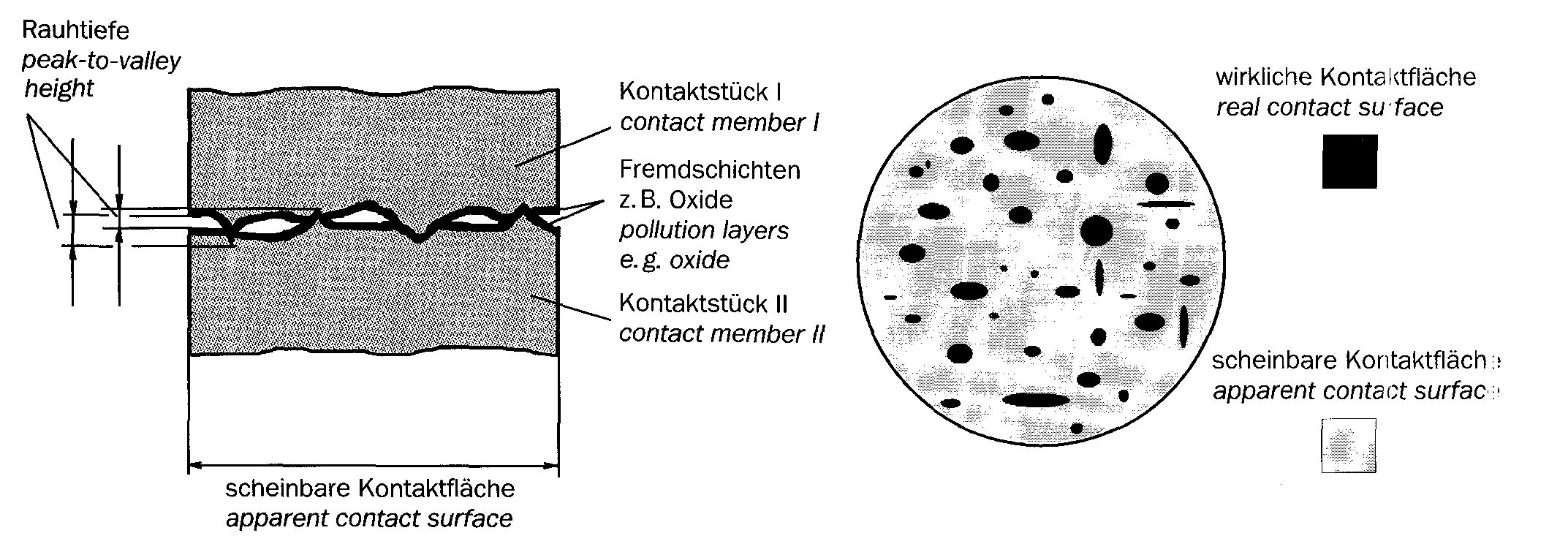

Basics of heavy contact technology:

- Only 10% of the complete contact surface is effective for heavy

current contacts.

- The assembly force is approx. 50 - 90% higher than the contact

force.

- Compensation of conductor creep has to be compensated.

- Long term curren bridges only starting with contact pressure

of 20 N/mm².

- Correct greasing of contact areas.

Important criteria are therefore:

- Deep knowledge of conductor (number of layers).

- Design of screws (material and thickness)

- Correct number of covers.

- Clamped connection must deliver enough elasticity to compensate

conductor creep.

- Correct choice of clamp material.

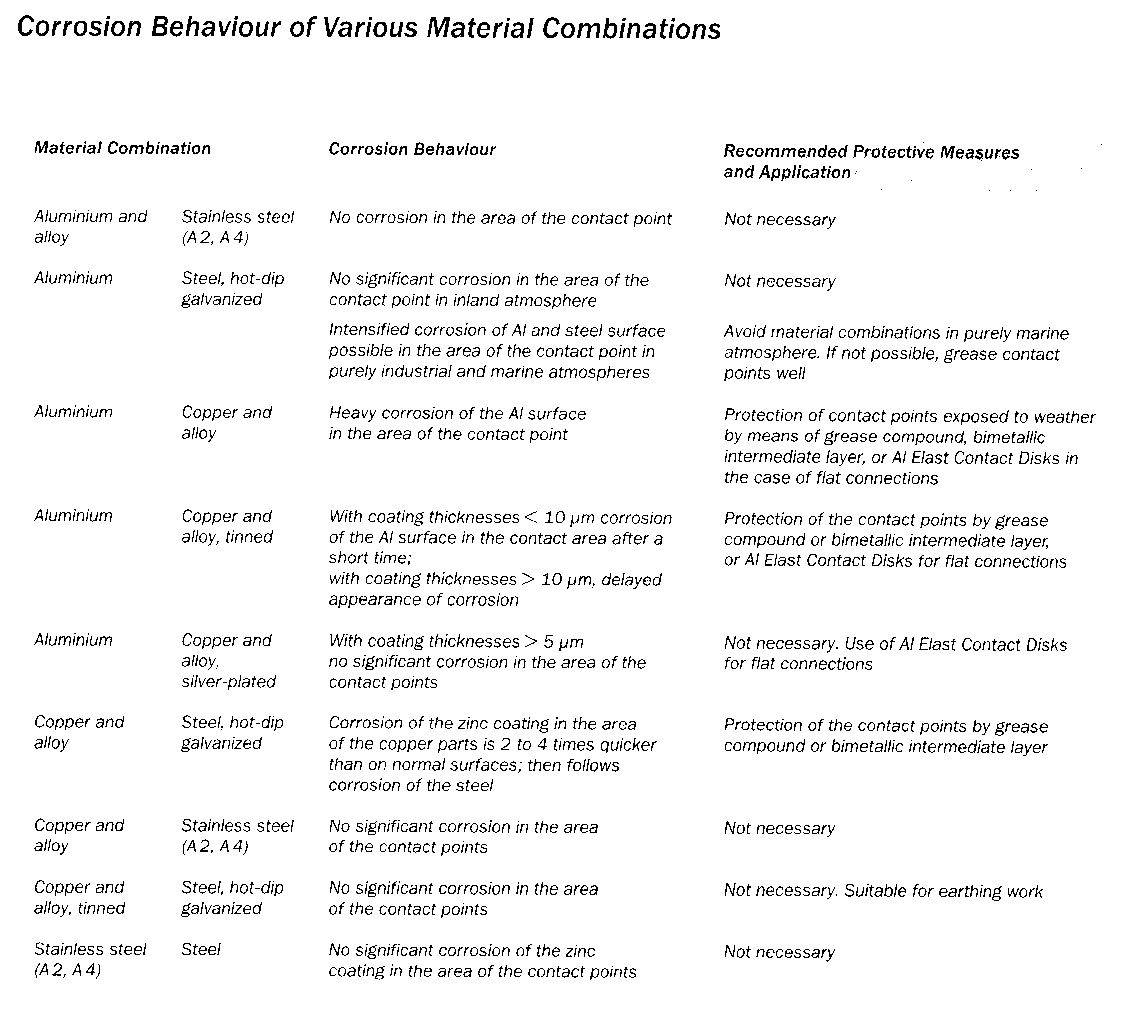

Improvement of contact surface through specific washers and plates